Sack Finish Concrete

Sack finish concrete. It will take a few tries to get the feel for doing it right but then you will be surprised how easy and fast it is to do. The completed surface should Published by. After dampening the surface and before it dries a mixture of dry cement and sand is rubbed over it with a wad of burlap or a sponge-rubber float to remove surplus mortar and fill the voids.

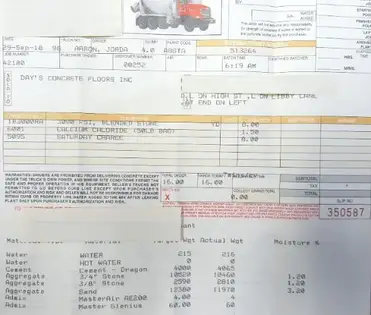

By Concrete Construction Staff. Concrete Materials and Admixtures Concrete Water-Cement Ratio. The stamped concrete finish is obtained by pressing the required patterns on the freshly levelled concrete.

It is used to patch and fill minor defects such as bug holes honeycomb and segregation to provide a finish of uniform appearance. Sack rub sack finish A finish for formed concrete surfaces designed to produce even texture and fill all pits and air holes. After dampening the surface and before it dries a mixture of dry cement and sand is rubbed over it with a wad of burlap or a sponge-rubber float to remove surplus mortar and fill the voids.

The sack method of specifying concrete is not very precise. Sack Rubbed Finish. Sacking produced a finish for cast-in-place concrete surfaces after fins from oils and bond breakers had been removed by filling in pits and air holes by dampening the surface and rub- bing mortar all over it.

- Friday Harbor WA. Starpatch Concrete Products Unit 5 - 6420 Beresford St. Burnaby BC Canada V5E 1B6.

Usually concrete is specified in terms of 28 day compressive strength which is typically at least 3000 psi. This type of concrete finish after completion of their construction looks similar to stones such as slates or flagstones brick tile or with proper skill they can look similar to wood. More from Concrete Construction.

Just remember to verify your quanties and discuss your project with us before ordering your ready mix concrete. Sack rub sack finish A finish for formed concrete surfaces designed to produce even texture and fill all pits and air holes.

Sacking - the practice of filling bugholes and other voids in concrete walls by rubbing a mixture of cement sand and water through a sack - can be very risky business.

After dampening the surface and before it dries a mixture of dry cement and sand is rubbed over it with a wad of burlap or a sponge-rubber float to remove surplus mortar and fill the voids. Sponge or sand finish is good not a steel troweled look. The sack method of specifying concrete is not very precise. Sacking and patching the traditional method for repamng concrete surface defects is often a grueling intensive process left over from an age when labor was relatively cheap and environmental and health hazards were not paramount concerns. Concrete Materials and Admixtures Concrete Water-Cement Ratio. The completed surface should Published by. When you rub out a new concrete wall you are applying a thin coat of Portland cement and literally rubbing it with a sponge float to create an attractive and durable finish. Stamped Finish Concrete. More from Concrete Construction.

About the Author Concrete Construction Staff. Please select from either the Starpatch Technik or Tennant product category menus below to browse our repair decorative and coatings product solutions. When is sack rubbing of exposed concrete necessary and what is the recommended method. - Friday Harbor WA. Sacking produces a finish for formed concrete surfaces designed to produce even texture and fill all pits and air holes. Sack Rubbed Finish. MIP Citadel Ultra-Hydro Stop Primer.

Post a Comment for "Sack Finish Concrete"